Don't miss our holiday offer - up to 50% OFF!

Standard Costing and Variance Analysis

Standard costs are essential in helping businesses make informed decisions that drive profitability and growth. The main difference between a standard and a budget is that a standard represents an expected cost, while a budget is a tool used to track actual costs. Standard costs are often used in pricing and decision-making, while budgets are typically used for financial reporting and planning. One of the first companies to use standard costing was Ford Motor Company.

Could you elaborate on the significance of a root-cause analysis?

- By setting standard costs based on historical data and industry benchmarks, organizations can anticipate expenses and plan their operations accordingly.

- This calls for using longer runs with lower costs because those items will account solely for their inventory expenses rather than both material’s price points combined like before.

- In small concerns, production cannot be properly scheduled since frequent changes in production conditions take place.

- If production has increased, but the standard cost remains the same, it’s likely that the standard cost is too low.

- This comparison helps businesses identify areas where they are overspending or under-spending and then take steps to correct those issues.

- Standard costing originated in the early 20th century as a method to streamline manufacturing processes and improve cost control.

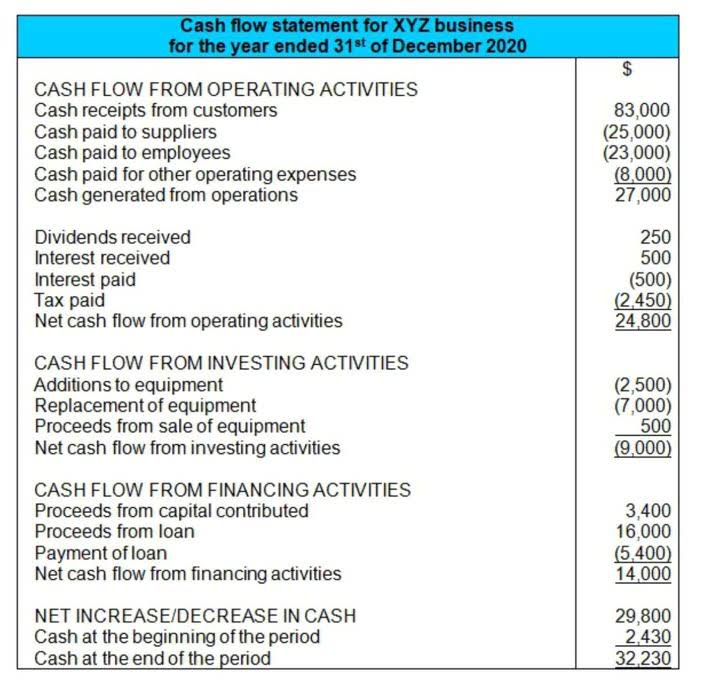

This system, which treats fixed manufacturing costs as a product cost, is required for external financial statements. The products in a manufacturer’s inventory that are completed and are awaiting to be sold. You might view this account as containing the cost of the products in balance sheet the finished goods warehouse. A manufacturer must disclose in its financial statements the amount of finished goods, work-in-process, and raw materials.

Direct Labor Variance

An “unfavorable” material price variance might result from buying higher-quality materials that Accounts Receivable Outsourcing reduce scrap, potentially a net win. Overhead variances include spending variances (actual overhead costs versus budget) and efficiency/volume variances (impact of production volume on overhead absorption). These tell you whether you’re controlling overhead costs and utilizing capacity effectively.

Best Practices for Standard Costing and Inventory Valuation

These standard costs are calculated based on historical data, industry norms, or cost models. They provide a standard benchmark to compare actual results, allowing businesses to assess their performance relative to expectations. Like the cost of goods sold, ending inventory reported on the balance sheet can have overstatements or understatements. Standard costs lower than actual costs result in understated ending inventory. Standard costs higher standard costing than actual costs result in overstated ending inventory. Therefore, the standard cost of producing one widget in this example would be $3.50.

Standard costing can impact employee behavior by creating pressure to meet standards, which can lead to positive outcomes like increased efficiency or negative outcomes like cutting corners. Staff training is crucial—everyone from production supervisors to accounting needs to understand not just how the system works, but why it matters to their job. Address resistance head-on by explaining benefits for each department, not just accounting. This oversimplification can lead to poor decisions about product mix and pricing, especially in companies with diverse product lines that consume resources in significantly different ways. Standard costing creates clear scorecards for your production departments. When everyone knows what “par” is supposed to be, it’s much easier to identify where inefficiencies happen.